Technical Background

Today's farm vehicles achieve traction by ballast.

The ballast creates friction between tire and soil as well as between soil particles under the tire. This friction transforms axle torque into forward force. The tractor moves forward. And the soil under the tire is compacted.

Tyres compress the soil slowly and steadily, preventing the intrusion of roots, water and air into the soil. The tyre tracks in a field reduce water infiltration and promote nutrient runoff and soil erosion. Beside directly reducing crop yields through soil compaction, tyre tracks also reduce the quality of drinking water, in the surrounding area, by promoting surface runoff that contains excess nutrients and pesticides. Furthermore, the current design of farm vehicles that generate friction on arable land is not energy-efficient.

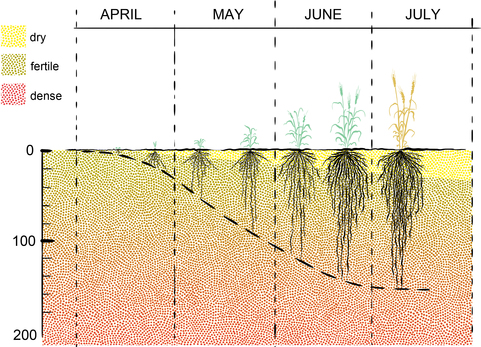

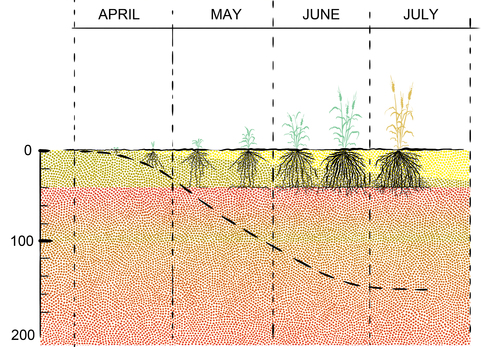

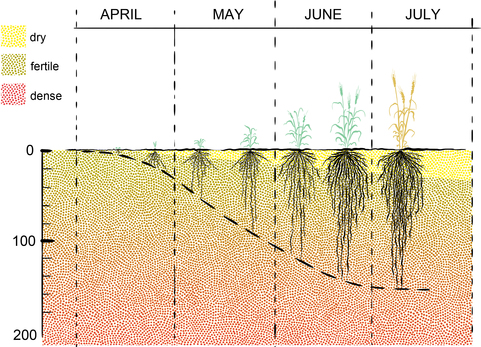

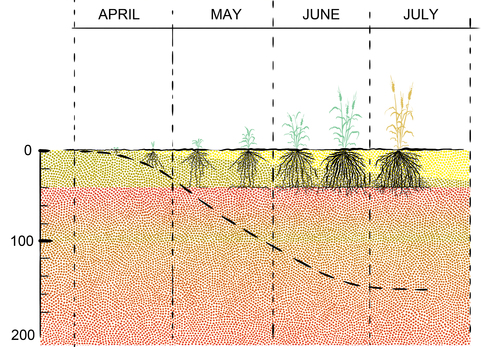

Above to the left you see an illustration of root growth over time in healthy soil. Wheat for example reaches a depth of 120cm, where the roots find important trace nutrients and where water is available even when the upper soil layers have dried out. To the right you see the effect of soil compaction. Roots grow flat and have no access to water in dry periods.

Currently, the most important approaches to prevent soil compaction are a greater spread of contact pressure by low pressure flotation tyres and concentrating traffic on a few highly compacted lanes (Controlled Traffic Farming).

Conservation tillage and no-till methods also protect soil by reducing the number of times soil is driven over.

These are all compromises. They merely concentrate the soil compaction over a specific area, thereby abandoning part of the area that could be cultivated, dispense with productive farm operations to protect the soil, or heavily increase dependency on pesticides.

They do not allow for a sustainable intensification of agriculture.

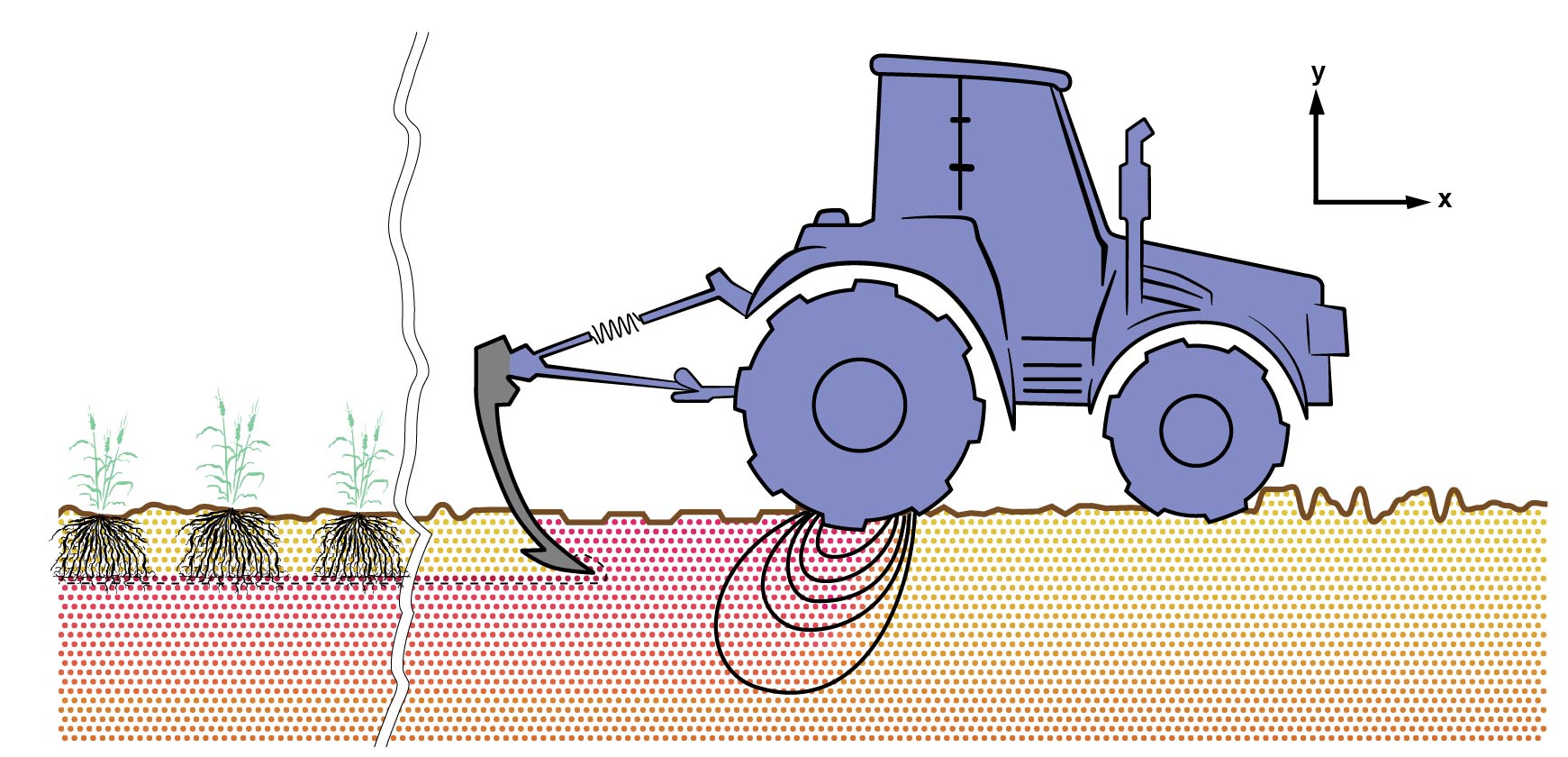

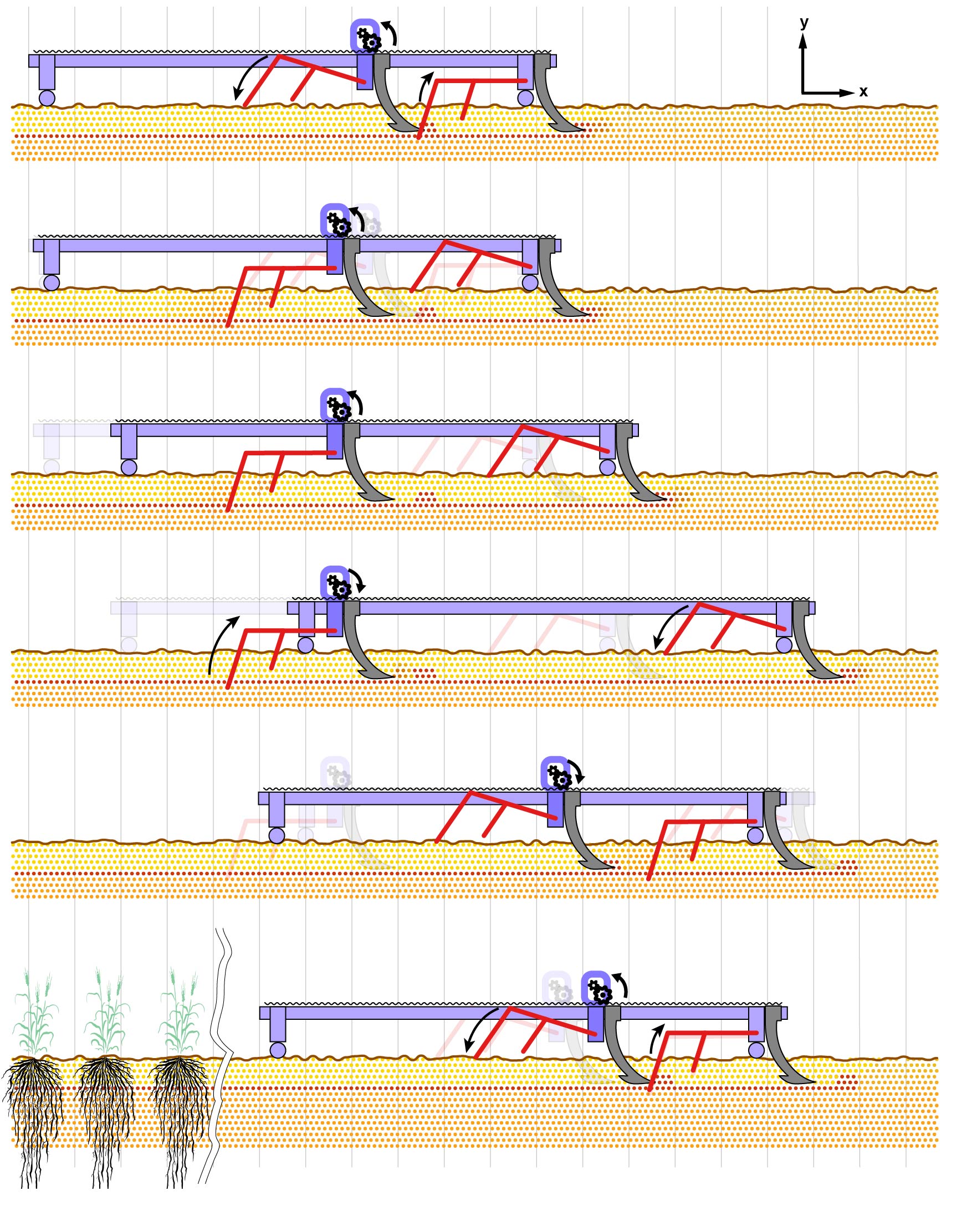

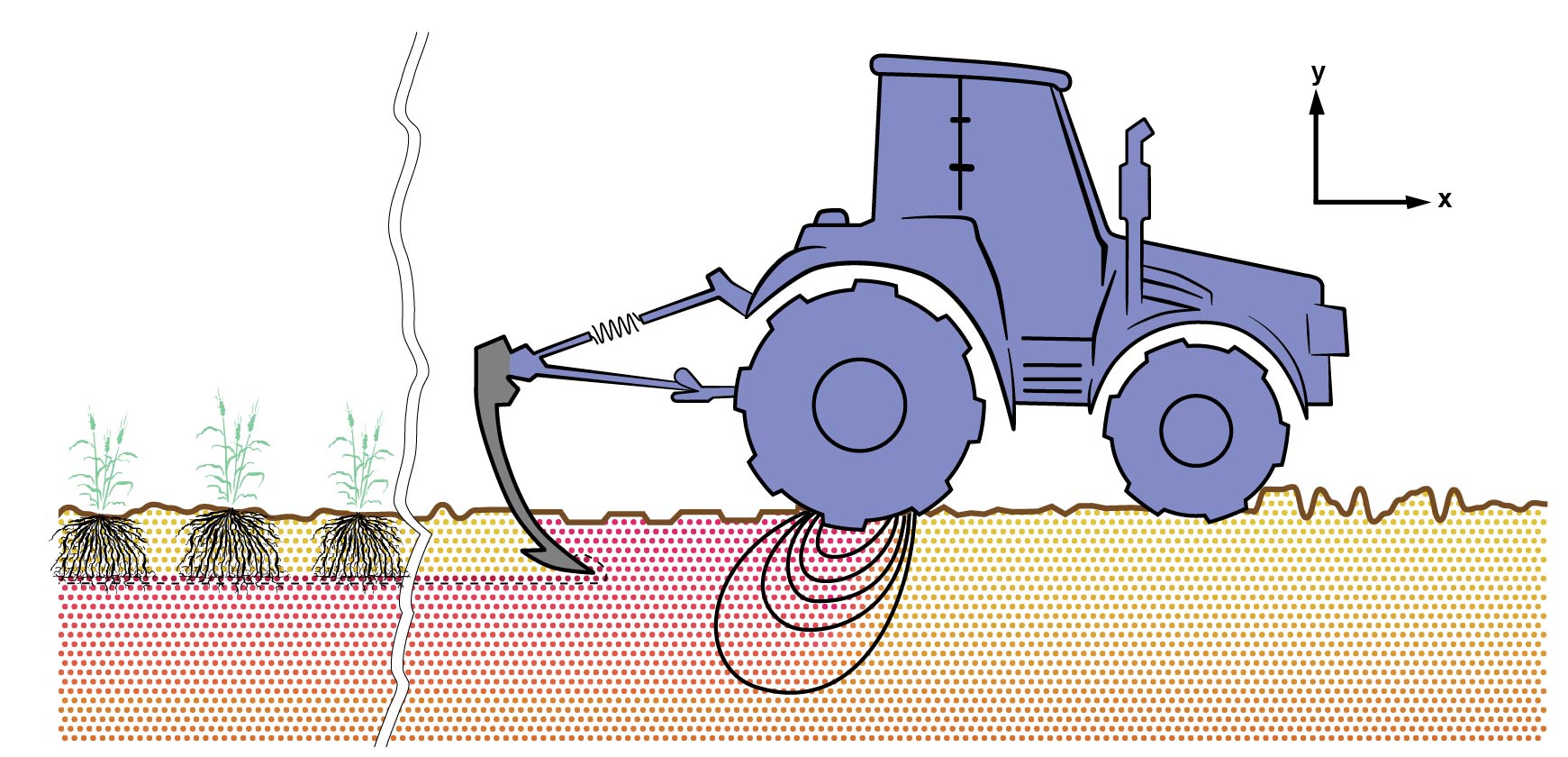

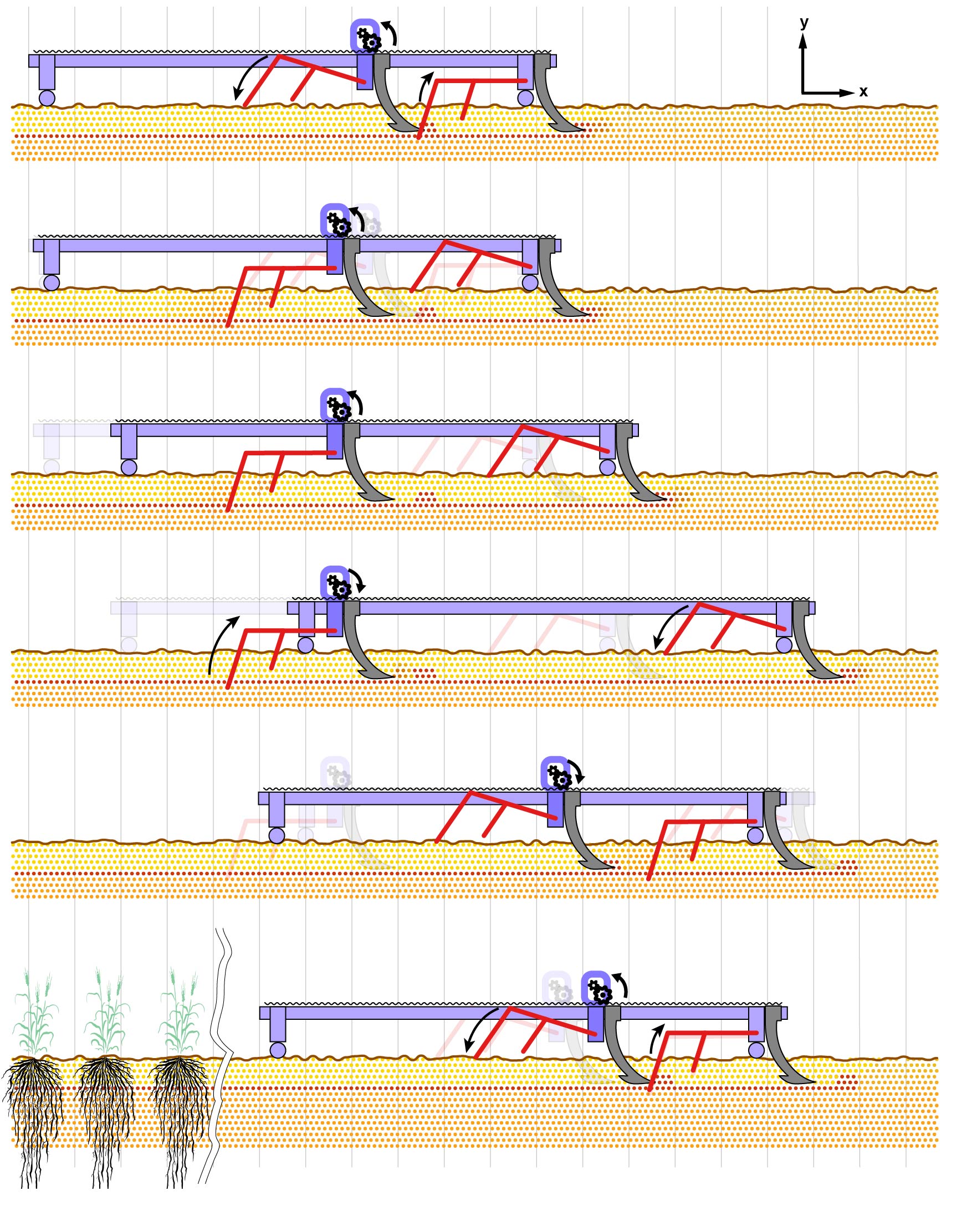

Traction can also be generated in the field by the interlock drive system, which penetrates narrow articulated spikes into the ground at regular intervals and pushes the vehicle from the spikes horizontally, avoiding the vertical pressure of the wheel which compacts the deeper soil horizon.

The penetration of the spikes into the ground can also have a positive influence on soil aeration and water infiltration and opens up the possibility for a comprehensive soil monitoring: as the spikes remain stationary in the soil for a short time (several seconds), sensors attached to the spikes can take measurement of important parameters such as pH and temperature

A spike anchored into the soil and linked to a push-pull mechanism may be used to propel a machine in an alternative motion pattern. Once half the motion pattern of the push-pull is complete a second spike provides anchorage and the first spike is pulled from the soil.

Without weed control, cash crop has to compete with wild plants for light, water, and nutrients.

Historically, weed control combined mechanical weed removal with management techniques like crop rotation. Modern agriculture relies heavily on herbicides to cut labour costs and to allow repeated planting of high value cash crops.

Food security must not dependent on herbicides.

Herbicides cannot be effective indefinitely, as weeds can and do evolve resistance.

Herbicides are used in enormous and ever increasing quanities, damaging the ecosystem and reducing biodiversity far beyond their immediate field of application.

Ecolological agriculture avoids most herbicides, but does not offer a satisfactory alternative, which reduces productivity.

See here for the position of the European Commission on herbicides.

Mechanical weeding is energy intensive and requires a high degree of precision.

Weed control by tractor consumes energy, such that ecological agriculture which uses it ironically has a larger carbon footprint.

The use of horse and ox-drawn equipment for weed control requires such a high degree of skill and physical ability that it has little economic advantage over weed control by hand.

Without herbicides, mechanical weeding is only necessary when the cash crop is small, as a larger crop does not allow the weeds to grow. Depending on the crop, mechanical weeding should to be applied in intervals of between three and six weeks, up to three times between planting and harvest.

In some climates, mechanical weeding also loosens the top soil, disrupting the capillary forces in the upper soil layer and preserving humidity.